As the Equipment Power Protection (EPP) development project nears completion, the focus has shifted from design to testing. Manufacturing multiple EPP units for ministry partners requires specific test equipment so that tests are done quickly and accurately, ensuring each EPP unit works precisely as intended.

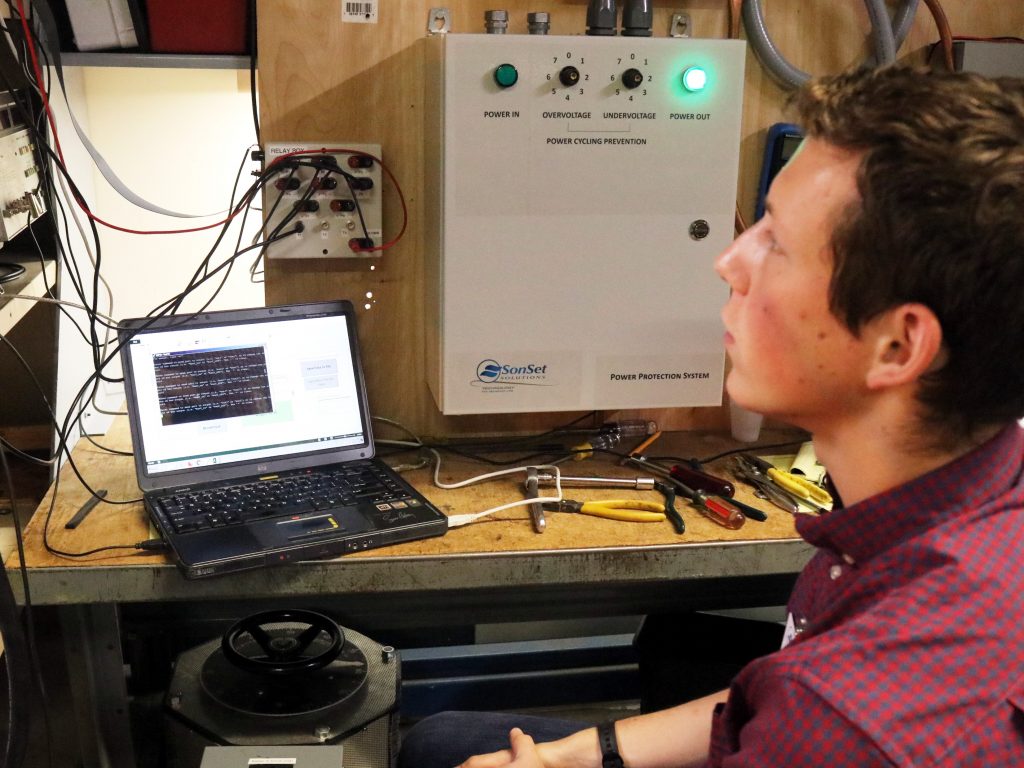

Springboarding from programming code and mechanical assembly done by summer interns Michael Koval and Liana Kriebel, SonSet Solutions’ engineer Mike Tapia has been creating and fine tuning the test automation process. With the click of a button, a series of tests take measurements in key places and in different ways, as if to say, “How long did it take the EPP to disconnect the equipment once it saw the high voltage? Did it function in the way we expected?” A small relay box controlled by a microcontroller helps automate this test, simplifying the process.

Protecting ministry partners’ equipment from electrical damage and ensuring it’s broadcasting the gospel message requires answering questions like, “Can we verify that the EPP will work with a specific amount of current running through the device? Will it save the equipment it was designed to protect?” Thanks to the Lord’s enabling of summer interns and SonSet Solutions engineers, the answer is a resounding, “Yes!”